- 32-bit processing

- Highly configurable feature set

- Scalable performance

- 32-bit embedded RTOS support

- Up to 8-stage pipeline

- Power & area optimized

- Up to dual-issue superscalar

RISC-V

Core IP Portfolio

Discover the industry’s broadest portfolio of RISC‑V cores, customizable for your specific application needs

Powering Innovation Across Industries

The SiFive® Core IP portfolio consists of four distinct families, each designed to address diverse computing demands: high-performance application processors, low-power embedded microcontrollers, highly scalable vector and matrix processors for AI and modern workloads, and solutions specifically designed for the automotive industry. Built on the RISC-V ISA and supported by flexible software and a global ecosystem, our core IP offers customers world-class performance and versatility.

Essential

The SiFive Essential™ family offers a wide range of silicon-proven, pre-defined embedded CPU cores or lets you use SiFive Core Designer to build a custom processor configuration tailored to your specific market and needs.

- Highly customizable to meet exact requirements

- Scales from 32-bit MCUs to 64-bit dual-issue

- Proven Innovation: billions of units shipped worldwide

Intelligence

SiFive Intelligence™ embraces a software-first approach to processor design, addressing the future needs of deploying ML and AI at the edge. It provides high-performance, scalable vector and matrix compute capabilities, adaptable to evolving workloads.

- Scalar + wide vector compute engines

- High bandwidth bus interfaces to control custom engines

- Highly scalable matrix computing solutions

Performance

SiFive Performance™ delivers maximum performance and throughput in a range of sizes and power profiles. These cores provide customers with highly efficient, feature-rich RISC-V scalar and vector computing capabilities, tailored for optimal balance and industry-leading results.

- High Performance 64bit Out of Order scalar engines

- Full support for RVA23 profile

- Optional vector compute engines across the portfolio

Automotive

SiFive Automotive™ solutions provide a range of high-end application and real-time processors, delivering industry-leading performance, minimal area, and low power consumption. ISO 21434, ISO 26262 ASIL B, ASIL D and split-lock certifications.

- High performance IP for IVI, ADAS and Central Compute

- Embedded cores for Zonal compute, safety islands, and microcontrollers

- Intelligence AI cores for all vehicle workloads, including ADAS/AD

SiFive Essential Family

- 64-bit processing

- No code size increase over 32-bit core

- Highly configurable feature set

- Scalable performance

- 64-bit embedded RTOS support

- Up to 8-stage pipeline

- Up to dual-issue superscalar

- Memory Management Unit providing virtual memory support

- Highly configurable feature set

- Scalable performance

- 64-bit rich OS support (including Linux)

- 8-stage pipeline

- Up to dual-issue superscalar

SiFive Intelligence Family

- 32-bit or 64-bit CPU

- 128-bit Vector Length

- SSCI and VCIX

- 512-bit Vector length

- Single Vector ALU

- VCIX (1024-bit)

- 1024-bit Vector Length

- Single/Dual Vector ALU

- VCIX (2048-bit)

- Scalable Matrix Engine

- 4 X300 cores per cluster

- 1 Cluster = 16 TOPS (INT8)

SiFive Performance Family

- Highly efficient, lowest power cores

- 3-wide out-of-order core

- Scalable up to 16 cores

- RVA22 with 1x128-bit Vectors/vector crypto

- RV64GBC capable core with Sv39/Sv48 Virtual Memory Support

- 3-wide out-of-order core

- Scalable up to 8 cores

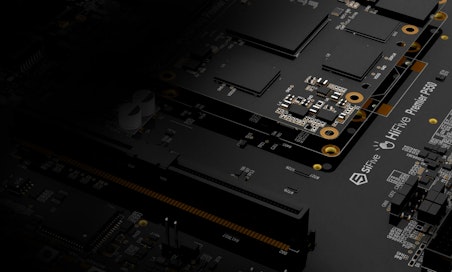

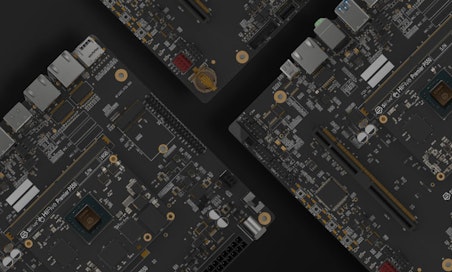

- Accelerating RISC-V adoption with HiFive Premier P550 development board

- High performance cores for general purpose applications

- 4-wide out-of-order core

- Scalable to up to 16 cores

- RVA22 with 2x128-bit Vectors/vector crypto

- Highest single threaded performance cores

- 6-wide, out-of-order core

- Scalable to 256 cores

- RVA23 with 2x128 bit vectors

- CHI bridge

- RAS Functionality

SiFive Automotive Family

- 32-bit 8 stage scalar

- Balanced performance and efficiency

- ASIL B, D

- 32-bit superscaler

- High performance and efficiency

- ASIL B, D

- 64-bit superscaler

- High performance embedded

- ASIL D